-

Product DescriptionCompany Info.<>

- Model:

- JXKLZ-310

- Processing customization:

- No

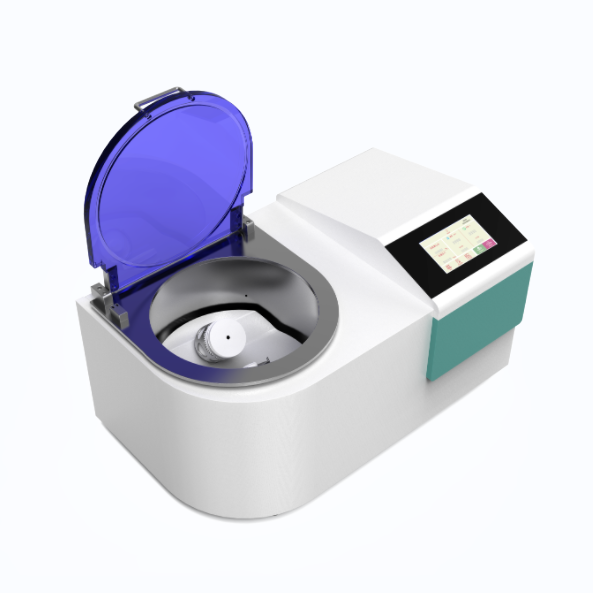

Vacuum Stirring Debubbler is a kind of equipment used to remove bubbles in liquid or slurry. It uses the principle of non-contact stirring centrifugal vacuum degassing to provide vacuum environment in the process of mixture stirring and degassing to accelerate the discharge of bubbles. Stirring and degassing time is generally about 3 minutes. Suitable for mixing and defoaming conductive/resistive materials such as gold/silver/carbon paste, new polymer materials, glass/ceramic paste and other sealing/insulating materials, chemical incubators, medical, food, single-liquid epoxy resin and other sealing materials/adhesives, LED fluorescent agent/silica gel and other molding materials.

Product Features:

1. The gear adopts spiral bevel gear processed by imported material MC901, with high transmission efficiency, stable transmission ratio and low noise;

2. Rotation and revolution * High centrifugal gravity of nearly 400G, strong dispersion and bubble removal, improve product quality and stability;

3, vacuum degassing, strong vacuum pump, from the material in the nano bubble;

4, no spiral blades, to achieve mixing and dispersion in the container, without damaging the material properties;

5, multi-functional applications, can store multiple groups of programs, to meet the needs of different materials mixing defoaming;

6, no need to clean, will not pollute the material does not damage the material (especially fibrous materials) properties;

7, human-computer interaction, easy to operate; ultra-small, ultra-light optimization design;Applications:

1. Photovoltaic semiconductor industry and related research institutes: LED and other electronic components production, touch screen (TP), thin film solar cell conductive paste materials, insulating adhesive, RFID printing conductive ink, PCB/FPC conductive ink, conductive adhesive ACD, printed electronic materials, electronic sealing materials and other high-end product materials, silver paste, silver nanoparticles, silver nanowires and LED/OLED/SMD/COB conductive silver adhesive, etc.;

2. Chemicals, cosmetics, etc.: fine chemical materials, cosmetics production, aluminum paste, adhesives, inks, fluorescent powder, nano powder materials, etc.;

3, automotive, aviation: automotive electronics technology, sensing technology;

4. Crafts production: such as silica gel material degassing;

5. Medical treatment: liquid medicine quality testing, medical materials, medicines, pharmaceuticals;Effect diagram before and after stirring and defoaming:

Product Application Examples:

1, in the blackberry juice concentrate processing, degassing process is to remove oxygen and bubbles, often using vacuum degassing method, adjust the vacuum to 60mbar. time for two minutes. * Finally, brown translucent pretreated blackberry juice without stratification and precipitation was obtained.

2. In the past, soybean water produced in the production process of soybean protein isolate was generally treated as production wastewater, resulting in waste of resources. Vacuum defoaming was used to remove the foam in the bean water, and then beer flavor beverage could be made after a series of treatments.

Vacuum centrifugal degassing (gas) is widely used in the field of cosmetics. After vacuum centrifugal degassing, the particle size of emulsion becomes smaller and the stability is improved; after vacuum centrifugal degassing, the viscosity of massage cream and skin lotion can be improved, and the viscosity is still maintained for three months.

4. In the whole production process of lithium ion battery, cell slurry stirring is one of the key links in the mixing and dispersion process. The vacuum stirring defoaming machine can uniformly stir the binder, conductive agent, cathode material and other materials within a few seconds to a few minutes, and remove bubbles, so as to avoid uneven stirring and nano-scale bubbles existing in the slurry affecting the performance and quality of lithium ion batteries.

5, UV light curing glue used in LED and other industries (such as epoxy resin glue), in the packaging process must be debubbled on the colloid, in order to avoid empty spots or other bad problems when dispensing, affecting the quality and adhesion of the glue point.

6, ink bubbles will lead to ink quality instability, such as uneven color, printing surface is not smooth and other problems. By removing bubbles through vacuum defoaming machine, can improve ink quality stability, ensure ink color uniformity, print quality stability.Performance parameters:

major parameter

parameter scale

Model:

JXKLZ-310

Usage:

Suitable for multicomponent materials (silicone, multicomponent epoxy, etc.) Dispersion, mixing, deaeration

Standard container:

300ml*2(HDPE 78x90) or 150ml*2(HDPE 60*72)

Capacity:

≤180ml

Revolution:

100-2000rpm stepless speed regulation, according to the actual needs of users arbitrary input, step 1rpm

Rotation:

Constant speed ratio 1:1

Set time:

0-1800s*5(five steps in total), continuous operation time 30min; conventional time within 1~3min

Parameter storage capacity:

10 groups

Vacuum degree of whole machine:

-95KPa; vacuum source: built-in advanced vacuum pump (14m3/h)

Vacuum settings:

Vacuum independent switch with vacuum delay function

Bearing:

Japan NSK bearings

Control system:

Man-machine dialogue, Chinese interface, touch screen operation

Balance regulation:

Double cup configuration balanced, single cup testable with weights

Transmission mode:

spiral bevel gear drive

How it works:

common rotation wingless centrifugal gravity mode

Open cover protection:

Open cover does not work

Applicable temperature and humidity:

10-40℃; 20-80%RH(no foggy moisture, can be)

Voltage:

AC220V±5%;1-Phase;50~60Hz

Rated power:

1500w

Appearance size:

L850xW520xH450mm

Weight of host:

100Kg

- Name(chinese)

- Name(English)

- Shanghai Jingxin Industrial Development Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Minhang District, Shanghai, China

- Nearby port

- Ningbo

Shanghai Jingxin Experimental Equipment Science and Technology Department is a high-tech enterprise specializing in the research and development, production, sales and service of life science instruments and reagents. The company is located in Shanghai Zizhu Science Park and adjacent to Shanghai Jiao Tong University. Shanghai Jingxin Experimental Equipment Science and Technology Department was formerly a branch office of Germany's FENGYUE Industrial Company in Shanghai. In 2009, the company's major shareholders jointly invested and cooperated with Germany's FENGYUE Industrial Company in production. While continuously improving the original products, it also focuses on technological innovation and continuously develops experimental instruments favored by customers. The company relies on a dynamic and imaginative team to continuously innovate and improve products. At the same time, the products are produced in strict accordance with ISO9001 standards, with integrated design, meticulous materials, precise processing, strict inspection of each instrument, and attention to the "Jingxin" brand. Advanced hardware and software also provide a more solid foundation for the production of high-quality products. Relying on stable product quality, high-quality after-sales service, and rigorous work style, products such as the "Tissuelyser Series Grinder" and "Semiconductor Refrigeration Technology Based" launched by our company have been favored and widely used in higher research institutes such as the Chinese Academy of Sciences, the Academy of Agricultural Sciences, and the Academy of Medical Sciences., as well as national key laboratories of colleges and universities such as Shanghai Jiao Tong University, Fudan University, Zhejiang University, Chinese University of Hong Kong, and Hong Kong Polytechnic University. With the advancement of scientific research and changes in technological revolution, many new demands will be born to make it more conducive to experiments and research, or to improve existing product technologies to make them more suitable for people's use. The direction we are committed to is to find out these potential needs, create new products, or embody, industrialize and market some conceptual products. Jingxin Technology will work hard to create a new business opportunity and industry with its partners.- Name(chinese)

- Name(English)

- Shanghai Jingxin Industrial Development Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Minhang District, Shanghai, China

- Nearby port

- Ningbo

Shanghai Jingxin Experimental Equipment Science and Technology Department is a high-tech enterprise specializing in the research and development, production, sales and service of life science instruments and reagents. The company is located in Shanghai Zizhu Science Park and adjacent to Shanghai Jiao Tong University. Shanghai Jingxin Experimental Equipment Science and Technology Department was formerly a branch office of Germany's FENGYUE Industrial Company in Shanghai. In 2009, the company's major shareholders jointly invested and cooperated with Germany's FENGYUE Industrial Company in production. While continuously improving the original products, it also focuses on technological innovation and continuously develops experimental instruments favored by customers. The company relies on a dynamic and imaginative team to continuously innovate and improve products. At the same time, the products are produced in strict accordance with ISO9001 standards, with integrated design, meticulous materials, precise processing, strict inspection of each instrument, and attention to the "Jingxin" brand. Advanced hardware and software also provide a more solid foundation for the production of high-quality products. Relying on stable product quality, high-quality after-sales service, and rigorous work style, products such as the "Tissuelyser Series Grinder" and "Semiconductor Refrigeration Technology Based" launched by our company have been favored and widely used in higher research institutes such as the Chinese Academy of Sciences, the Academy of Agricultural Sciences, and the Academy of Medical Sciences., as well as national key laboratories of colleges and universities such as Shanghai Jiao Tong University, Fudan University, Zhejiang University, Chinese University of Hong Kong, and Hong Kong Polytechnic University. With the advancement of scientific research and changes in technological revolution, many new demands will be born to make it more conducive to experiments and research, or to improve existing product technologies to make them more suitable for people's use. The direction we are committed to is to find out these potential needs, create new products, or embody, industrialize and market some conceptual products. Jingxin Technology will work hard to create a new business opportunity and industry with its partners. -

Send your message to this supplier*From:*To:

Ms. shaoqiong

*Message:

Ms. shaoqiong

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.